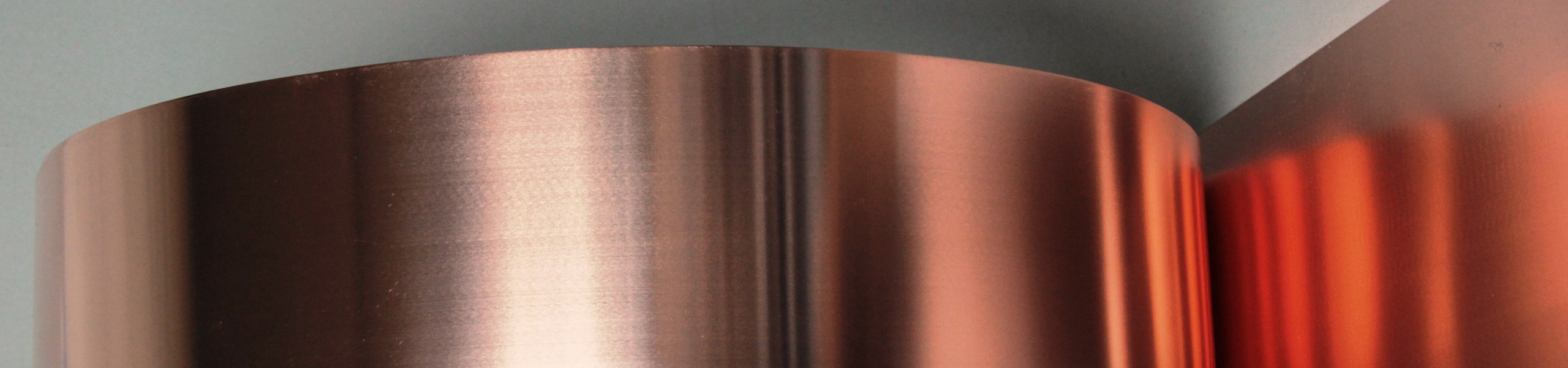

Copper coated

Product's conditions:

cold rolled and copper coated steel strip introduces the advantages of copper joined to steel like - high stregth and high level of forming, good material´s costs. We can replace copper alloys by our products of copper coated steel strips. Mainly in electronics, there is this kind of copper coated steel strip highly appreciated because of good conductivity, and contact ability of copper. Copper coated steel is suitable further next welding and soldering process.

End use:

automotive industry, electronics, consumer industry

Dimensions:

Width: 4-300 mm

Thickness: 0,10 - 2,00 mm

Steel grades acc. to EN - DC01, DC03, DC04

Surface finishes:

N = non-polished

K = brushed, is with slight desing on both sides of the strip

L = one side polished

2L = both sides polished

1. By surface finish brushed loses the metal coating layer max. 25 % from the total of metal coating thickness

2. By surface finish one side polished loses the metal coating layer max. 15 % from the total of metal coating thickness and by surface finish both sides polished loses the metal coating layer max. 30 % from the total of metal coating thickness.

| Marking | Thickness of coating | |

|---|---|---|

| µm | g/m2 | |

| CU | 3-4 | 25-35 |

| SCU | 4,5-5 | 40-50 |

| VSCU (µm/µm.) | Max. 10/10 | Max. 180 |